鉄鋼やアルミニウムの原料から無数の産業向け部品が生み出される、要求の厳しい金属加工の世界において、Tiger金属せん断機は、堅牢なパワーと精密な切断能力の象徴となっています。「Tiger」という名前は、文脈によっては繊維機械を連想させるかもしれませんが、金属加工の世界では、特定のブランドに関連付けられることが多く、また、板金を効率的かつ正確に加工するために設計された、耐久性が高く信頼性の高い油圧せん断機を指す俗称となっています。

コア機能:きれいでまっすぐなカット

タイガー金属せん断機は、本質的には油圧式ギロチンせん断機です。主な用途は、金属板、プレート、そして時にはアングル材やフラット材などの構造部材を、きれいに直線的に切断することです。鋸引きやプラズマ切断とは異なり、せん断は切断ロス(材料の無駄)を最小限に抑え、切断端面付近の金属特性を変化させる熱を発生しません。そのため、以下の用途に最適です。

1. ブランクのサイズ調整: 大きなシートを扱いやすいワークピースに切断し、その後の加工 (打ち抜き、曲げ、溶接) に使用します。

2. エッジのトリミング: 部品から不均一な材料や余分な材料を除去します。

3. 直線カット:多くの場合、二次仕上げなしで正確な直線カットを作成します。

獣の解剖学:主要構成要素

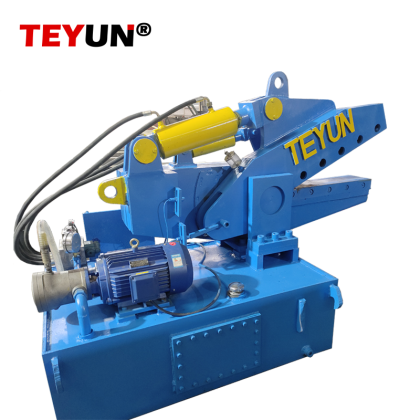

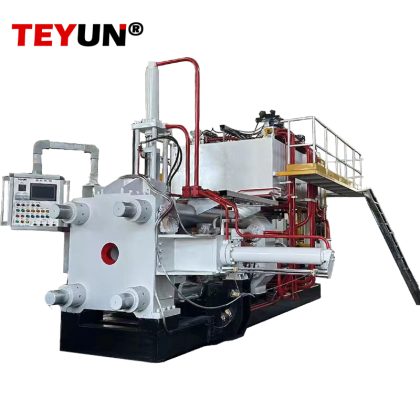

一般的な Tiger スタイルの油圧せん断機には、いくつかの重要なコンポーネントが備わっています。

1. 堅牢なフレーム:溶接された頑丈なスチールフレームが基盤となり、巨大な切断力をたわむことなく吸収し、切断精度を保証します。この堅牢な構造こそが、「Tiger」の名声の証です。

2. 油圧システム:強力な油圧シリンダーが、上刃を金属に打ち込むために必要なトン単位の巨大な力を生み出します。このシステムにより、スムーズで制御された切断サイクルと、材料の厚さや種類に応じた力の調整が可能になります。

3. ブレード:精密研磨された硬化鋼製ブレードは、この機械の心臓部です。上刃(可動式)は通常、傾斜(角度)しており、幅方向に沿って段階的に切断することで必要な切断力を低減します。下刃(固定式)は、その反力を生み出します。ブレードクリアランスは重要であり、材料の厚さに合わせて調整可能です。

4. ホールドダウンシステム:油圧式または機械式のクランプが、切断開始前にワークピースをしっかりと固定します。これにより、材料の滑り、歪み、危険なキックバックを防ぎ、安全性を確保し、バリを最小限に抑えたきれいな切断を実現します。

5. バックゲージ:精度にとって非常に重要な機能です。これは、CNC制御または手動で設定する可動式のストッパーで、オペレーターはこれに板金を当てます。これにより、所定の長さで高精度かつ再現性の高い切断が可能になります。

6. 制御システム:現代のTigerシアーは、シンプルなフットペダル/手動制御から高度なCNCシステムまで、幅広い制御システムを備えています。CNCシステムにより、プログラム可能なバックゲージ位置決め、刃先ギャップの自動調整、サイクルカウント、そして大規模な製造ラインへの統合が可能になります。

「タイガー」という呼び名:ブランドと評判

金属せん断における「Tiger」という名称は、多くの場合、非常に耐久性が高く、強力で信頼性の高い油圧せん断機を製造することで知られる特定のメーカーに由来しています。TigerStop(ソーストップで有名ですが、せん断用途も有しています)のようなブランドや、「Tiger」という名称を使用した歴史あるメーカーは、以下の点で定評のある機械を製造してきました。

比類のない強度:厚板鋼のせん断が可能。

頑丈な構造: 忙しい製造工場の過酷な環境に何十年も耐えられるように構築されています。

精度: 重い負荷がかかっても精度を維持します。

信頼性: ダウンタイムが最小限で、メンテナンスが容易です。

時間が経つにつれて、「Tiger Shear」は、ティッシュペーパーの「Kleenex」のように、ショップで大型で強力かつ信頼性の高い油圧式剪断機を指す一般的な用語になる可能性があります。

虎が歩く場所:応用

タイガーの金属鋏は、重工業から軽工業まであらゆる製造業に欠かせません。

構造用鋼材の製造: 梁、柱、ブラケット、ベースプレート用の切断プレート。

タンクおよび容器の製造: 円筒形または長方形のタンクの大型シートのサイズを決定します。

重機:鉱業、農業、建設機械の部品を製造します。

造船:船体、甲板、隔壁用の板材を切断します。

一般ジョブショップ: さまざまな金属や厚さの多様な切断作業を処理します。

HVAC: ダクトの金属板を切断します (ただし、より軽いゲージの場合は、小型の鋏で処理されることが多いです)。

メリット:Powerを選ぶ理由

高い生産性: 特に CNC バックゲージを使用した場合、直線カットのサイクル タイムが高速になります。

きれいなカット: 直線のエッジを生成するため、二次仕上げは最小限で済みます。

材料効率: 鋸引きに比べて切断部分の損失が最小限に抑えられます。

汎用性: 幅広い材質 (スチール、ステンレス、アルミニウム) と厚さに対応します。

耐久性: 厳しい条件下でも長寿命を実現できるように構築されています。

安全性: 一体型のホールドダウンとガードにより、それほど洗練されていない機器に比べてオペレーターのリスクが大幅に軽減されます。

その

タイガー金属せん断機

現代の金属加工に求められるパワーと精度を体現しています。特定の老舗ブランドを指すにせよ、単に堅牢な油圧式鋏のクラスを象徴するにせよ、その役割は根幹を成しています。重厚な金属材料を高速、正確、そしてクリーンな直線切断で切り出すことで、原材料を精密なワークピースへと変貌させ、数え切れないほどの製造工程の基盤を築きます。その堅牢な構造と容赦ない性能は、まさに現場の「虎」、板金加工を操るパワフルで不可欠な存在です。

住所 : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

住所 : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский español

español العربية

العربية Tiếng Việt

Tiếng Việt 中文

中文

IPv6ネットワークをサポート

IPv6ネットワークをサポート