水平梱包機:リサイクルと廃棄物管理の効率化の原動力

November 05, 2025

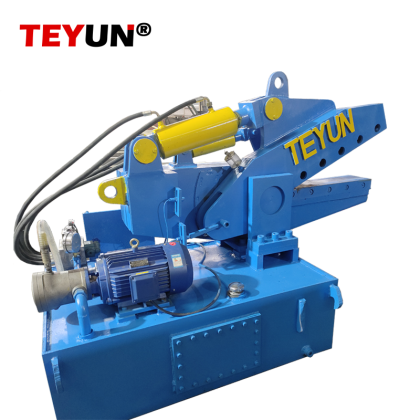

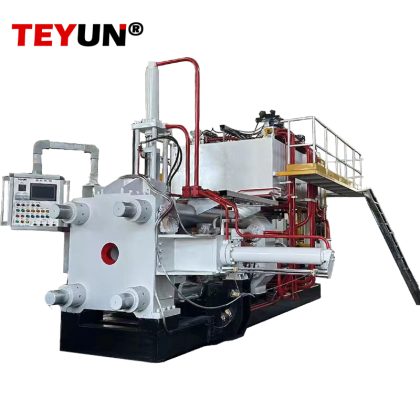

リサイクルセンター、製造工場、そして物流倉庫といった活気に満ちた世界において、業務効率と環境への責任を果たす上で欠かせない機器が一つあります。それが水平圧縮機です。この強力な主力機械は、大量のばらばらのリサイクル材や廃棄物を、密度が高く、扱いやすく、輸送しやすいベールに圧縮するために設計されています。垂直圧縮機とは異なり、水平圧縮機は、その名の通り水平面上で動作し、ラムが左右に動くことで、長く固定されたチャンバー内で材料を圧縮します。

水平型梱包機の基本原理は単純明快かつ非常に効率的です。段ボール、紙、プラスチックフィルム、繊維、アルミ缶などの非鉄金属などの材料は、通常はコンベアベルトまたは手作業で開放型ホッパーに投入されます。チャンバーが所定の充填レベルに達すると(手動または自動システムによる)、油圧ラムが作動します。高圧油圧システムで駆動されるこの頑丈な鋼板であるラムは、チャンバーの全長にわたって移動し、大きな力で材料を圧縮します。このサイクルは、最適な密度に達するまで数回繰り返されます。最後に、機械は自動的に圧縮されたブロックをワイヤーまたはストラップで結び、取り扱い可能な完璧な長方形の梱包材を排出します。

水平ベーラーを導入するメリットは大きく、多面的です。まず第一に、比類のない容積削減効果があります。材料を圧縮することで、保管スペースと輸送コストを大幅に削減できます。かつてはトラック1台分の段ボールで満杯だったものが、数個の整然と積み重ね可能なベールに凝縮されます。これは、運送費の削減と施設レイアウトの簡素化に直結します。さらに、これらの高密度ベールは貴重な資源です。リサイクル業者や製紙工場は、清潔で圧縮されたベールに高額を支払うため、廃棄物を収益源へと転換できます。水平ベーラーは、破片を封じ込め、火災の危険性を低減し、散乱を最小限に抑えることで、職場の安全と衛生の向上にも貢献します。

異なる運用規模に合わせて、主に2つの構成があります。2ラム式(クローズドドア)ベーラーは、大量生産に最適なパワーユニットです。メインラムが最終ベールを形成する前に材料を圧縮するプレプレスチャンバーを備えており、連続供給と最大のベール密度を実現します。シングルラム式(オープンエンド)ベーラーはよりコンパクトなソリューションで、中量生産に最適です。材料を供給し、1つのラムが圧縮と排出の全工程を実行します。

小売店のバックルームで途切れることなく流れ続ける段ボールの処理から、農業廃棄物の管理、あるいはリサイクル品を鋳造工場へ出荷するための準備まで、水平梱包機は欠かせない資産です。これは実用的なエンジニアリングの証であり、廃棄物管理における物流面と経済面の課題を、合理化され、収益性が高く、持続可能なオペレーションへと変革します。この技術への投資は、企業の収益向上だけでなく、循環型経済への積極的な貢献にもつながり、貴重な材料の回収と再利用を確実にします。

住所 : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

住所 : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский español

español العربية

العربية Tiếng Việt

Tiếng Việt 中文

中文

IPv6ネットワークをサポート

IPv6ネットワークをサポート