テユン

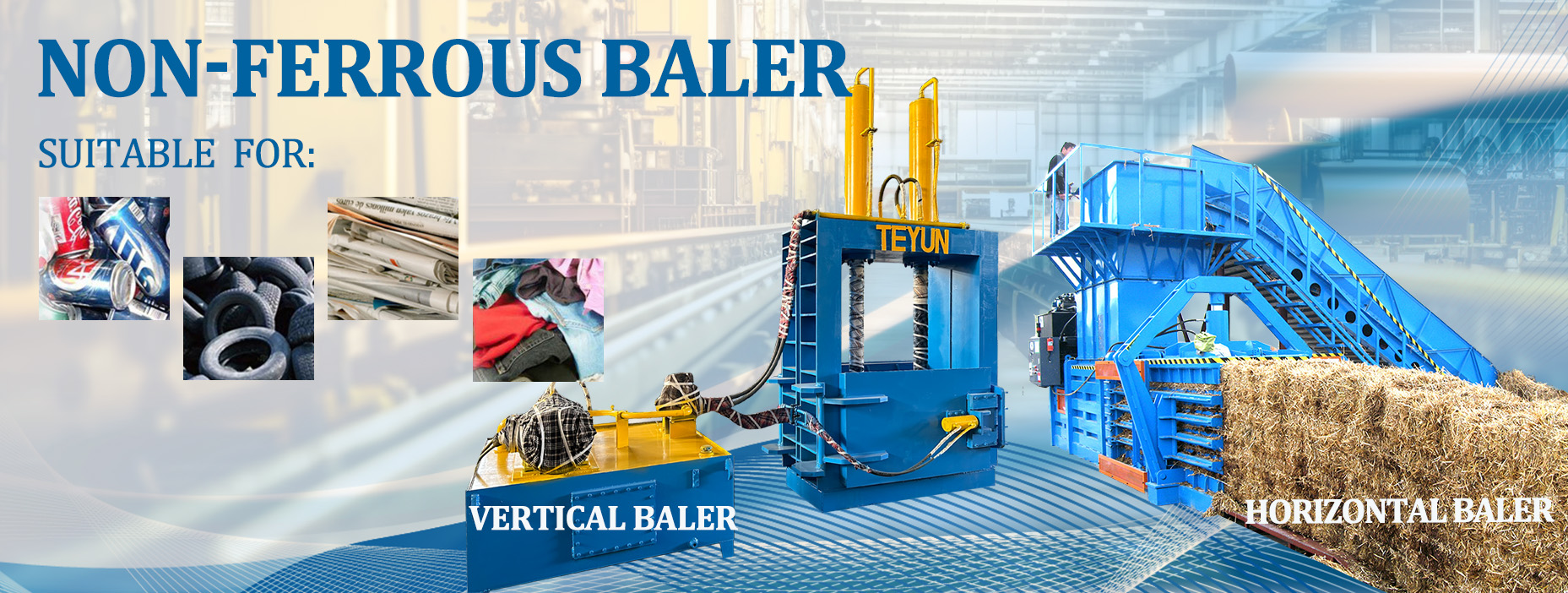

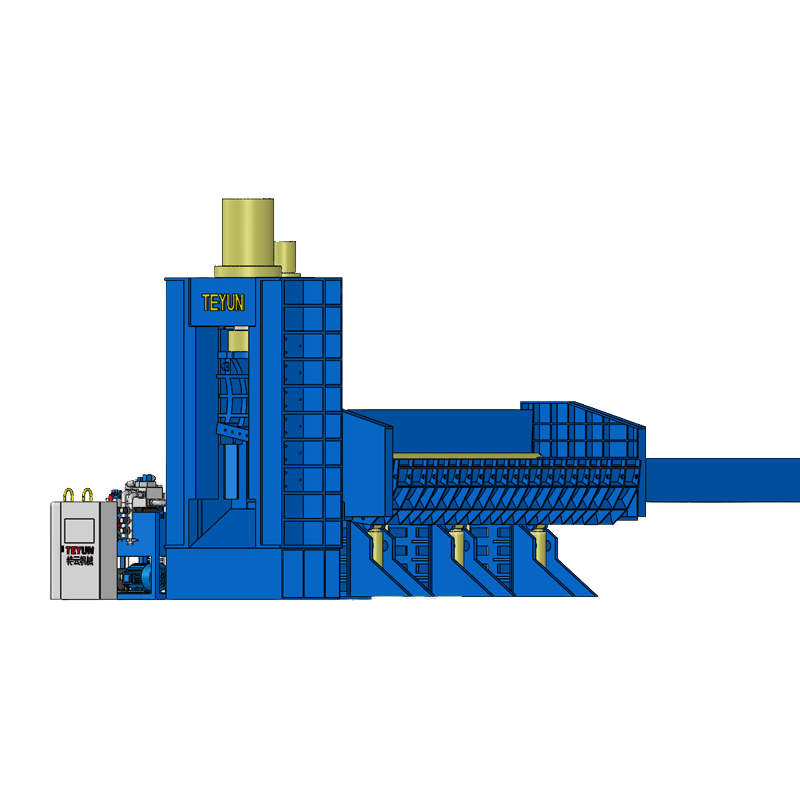

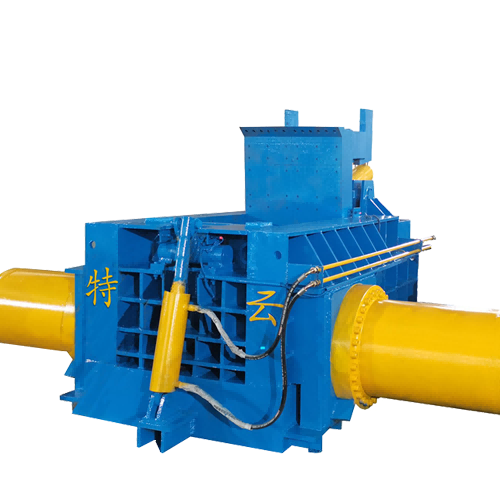

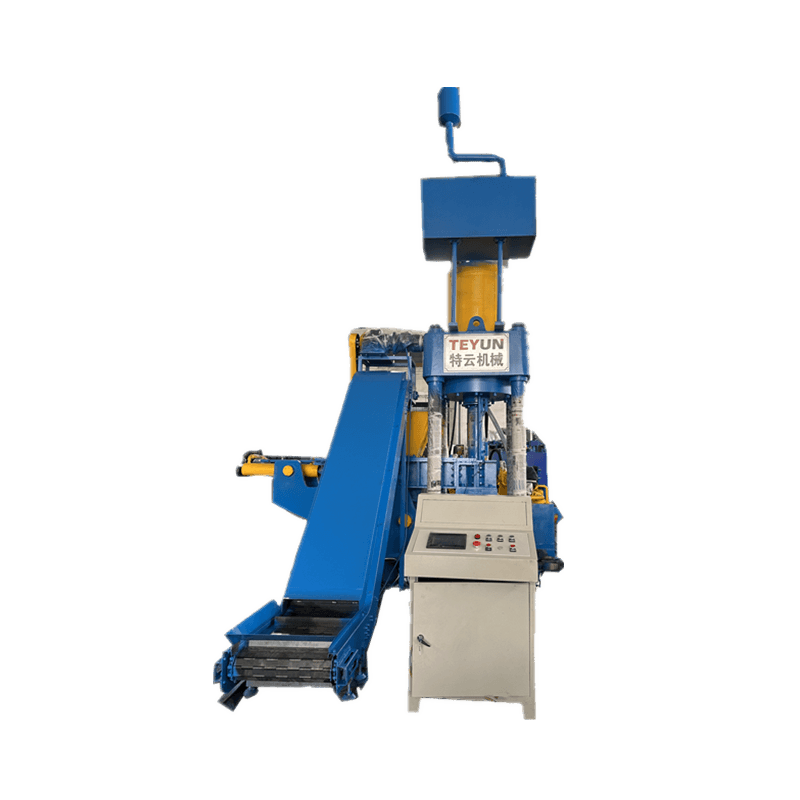

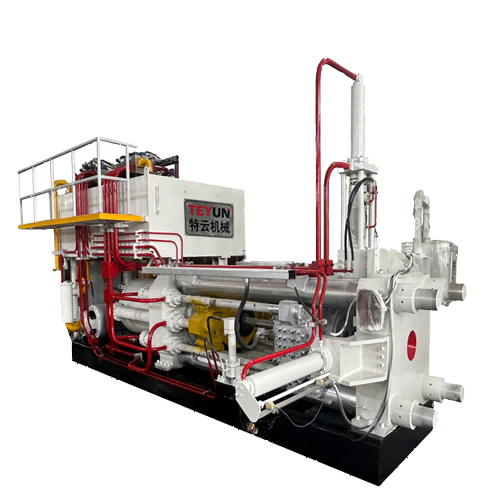

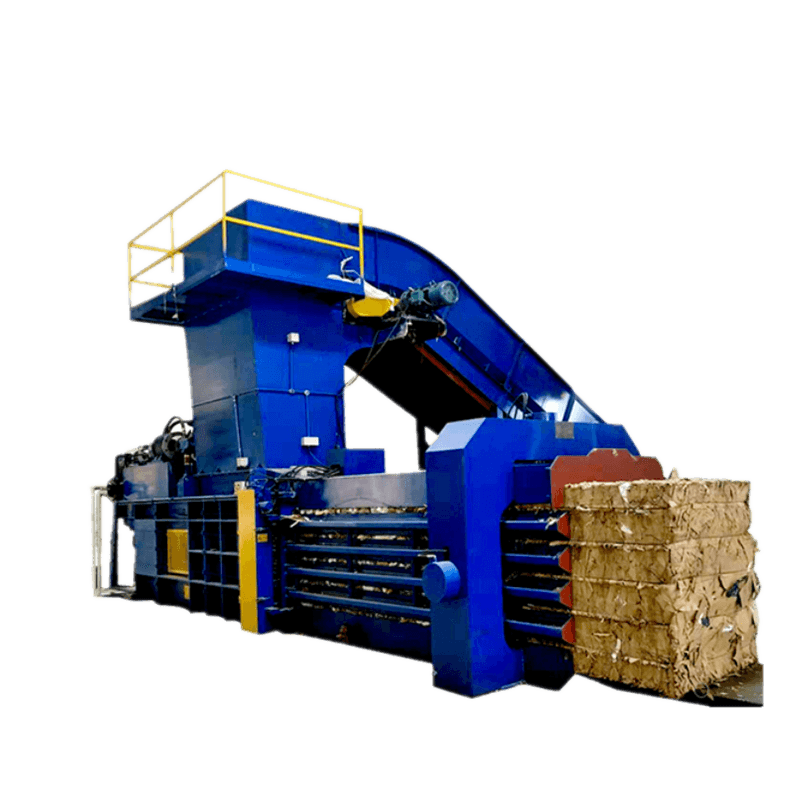

teyun„ĀĮ1997ŚĻī„Āꍮ≠Áęč„Āē„āĆ„ÄĀ20ŚĻīšĽ•šłä„Āģś≠īŚŹ≤„ĀĆ„Āā„āä„Āĺ„Āô. teyun„ĀĮ„ÄĀŤ®≠Ť®ą„Ā®Ť£ĹťÄ†„Āęťē∑ŚĻī„ĀģÁĶĆť®ď„āíśĆĀ„Ā§„Éó„É≠„ĀģŤ£ĹťÄ†šľĀś•≠„Āß„Āô„Äā ś≤ĻŚúßś©üśĘį .Śľ∑Śäõ„Ā™śäÄŤ°ďŚäõ„Āßšł≠ŚõĹ„Āß„Āē„Āĺ„ĀĖ„Āĺ„Ā™ś≤ĻŚúßś©üŚô®„āĄťáĎŚĪěś©üśĘįś©üŚô®„āíŤ£ĹťÄ†„Āô„āčšłĽŤ¶ĀšľĀś•≠„Āß„Āô,ťęėŚļ¶„Ā™Ť£ĹťÄ†ś©üŚô®„Ā®ŚģĆŚÖ®„Ā™„ÉÜ„āĻ„ÉąśĖĻś≥ē.šłĽŤ¶ĀŤ£ĹŚďĀ„Āę„ĀĮTY81„ā∑„É™„Éľ„āļťáĎŚĪěś≤ĻŚúß„Éô„Éľ„É©„Éľ,TY43„ā∑„É™„Éľ„āļ„ÉĮ„Éč„ĀĆŚźę„Āĺ„āĆ„Āĺ„Āôś≤ĻŚúß„Āõ„āďśĖ≠ś©ü,TY15„ā∑„É™„Éľ„āļ„ā¨„É≥„Éą„É™„Éľ„Āõ„āďśĖ≠ś©ü,TY83„ā∑„É™„Éľ„āļś≤ĻŚúß„āĻ„āĮ„É©„ÉÉ„ÉóśĘĪŚĆÖś©ü,TYPMŤá™ŚčēŚŹ§ÁīôśĘĪŚĆÖś©ü„Ā™„Ā©. ÁßĀ„Āü„Ā°„ĀĮŚłł„Āę„ÄĆŚģüÁĒ®ÁöĄ,ťĚ©śĖįÁöĄ,ŚÖąťßÜÁöĄ„Āč„Ā§ťÄ≤ŚŹĖÁöĄ".Ť®≠Ť®ą„ĀģŤĪäŚĮĆ„Ā™ÁĶĆť®ď„Ā®ś©üŚô®„ĀģŚá¶ÁźÜ„Āä„āą„Ā≥Ť£ĹťÄ†„ĀģŚĄ™„āĆ„ĀüŤÉĹŚäõ,„āíťĀĶŚģą„Āó„ÄĀ„Āē„Āĺ„ĀĖ„Āĺ„Ā™ťĚěś®ôśļĖ„Āģś≤ĻŚúßś©üśĘį„ā퍮≠Ť®ą„Āä„āą„Ā≥Ť£ĹťÄ†„Āß„Āć„Āĺ„Āô„ĀäŚģĘśßė„ĀĆťĀłśäě„Āó„ĀüÁČĻŚą•„Ā™Ť¶ĀšĽ∂„ĀęŚŅú„Āė„Ā¶.šł≠ŚõĹ,šłĽŤ¶Ā„Ā™ŚĽÉś£ĄÁČ©„É™„āĶ„ā§„āĮ„ÉęšľöÁ§ĺ,Ś§ßŤ¶Źś®°Ť£ĹťČĄśČÄ,Ť°õÁĒü„ā∑„āĻ„É܄Ɇ,„Ā™„Ā©.,„ĀäŚģĘśßė„ĀęŚģĆŚÖ®„Ā™„āĹ„É™„É•„Éľ„ā∑„Éß„É≥„ā휏źšĺõ„Āó„Āĺ„Āô. ŚĹďÁ§ĺ„ĀģŤ£ĹŚďĀ„ĀĮśó•śú¨„ĀꍾłŚáļ„Āē„āĆ„Ā¶„ĀĄ„Āĺ„Āô,„É≠„ā∑„āĘ,„ā™„Éľ„āĻ„Éą„É©„É™„āĘ,ÁĪ≥ŚõĹ,ŤčĪŚõĹ,„ÉČ„ā§„ÉĄ,„Āä„āą„Ā≥„ĀĚ„ĀģšĽĖ„ĀģŚõĹ„Ā®ŚúįŚüü.ŚĹďÁ§ĺ„ĀģťęėŚďĀŤ≥™„Āģ„ÉĎ„Éē„ā©„Éľ„Éě„É≥„āĻ„Ā®„āĶ„Éľ„Éď„āĻ„ĀĆŚčĚ„Ā°„Āĺ„Āó„ĀüśĶ∑Ś§Ė„Āģ„Éź„ā§„ɧ„Éľ„ĀģŤ™ćŤ≠ė„Ā®Ť≤∑„ĀĄśąĽ„Āó.ŚźĆśôā„Āę,šłÄťÉ®„ĀģŚõĹ„Āß„ĀĮ,ÁŹĺŚúį„ĀģŚõĹ„Āę„āĶ„Éľ„Éď„āĻ„ā휏źšĺõ„Āô„āč„ÉĖ„É©„É≥„ÉČ„ā®„Éľ„āł„āß„É≥„Éą„ā퍮≠ÁĹģ„Āó„Āĺ„Āó„Āü.šĽ£ÁźÜŚļó„ÉĀ„Éľ„Ɇ„ĀꌏāŚä†„Āó„Ā¶ś•Ĺ„Āó„ĀĄŚćĒŚäõ„āíŚßč„āĀ„Ā¶„ĀŹ„Ā†„Āē„ĀĄ„Äā .

Nanjing Teyun Machinery Manufacture Co., Ltd. 1997ŚĻī„Āꍮ≠Áęč„Āē„āĆ„ÄĀ20ŚĻīšĽ•šłä„Āģś≠īŚŹ≤„ĀĆ„Āā„āä„Āĺ„Āô. teyun„ĀĮ„ÄĀŤ®≠Ť®ą„Ā®Ť£ĹťÄ†„Āßťē∑ŚĻī„ĀģÁĶĆť®ď„āíśĆĀ„Ā§„Éó„É≠„ĀģŤ£ĹťÄ†šľĀś•≠„Āß„Āô„Äā ś≤ĻŚúßś©üśĘį .Śľ∑Śäõ„Ā™śäÄŤ°ďŚäõ„āíŚāô„Āą„Āüšł≠ŚõĹ„Āß„Āē„Āĺ„ĀĖ„Āĺ„Ā™ś≤ĻŚúßś©üŚô®„āĄťáĎŚĪěś©üśĘįś©üŚô®„āíŤ£ĹťÄ†„Āô„āčšłĽŤ¶ĀšľĀś•≠„Āß„Āô,ťęėŚļ¶„Ā™Ť£ĹťÄ†ś©üŚô®„Ā®ŚģĆŚÖ®„Ā™„ÉÜ„āĻ„ÉąśĖĻś≥ē.šłĽŤ¶ĀŤ£ĹŚďĀ„Āę„ĀĮTY81,TY83,TYPM„ā∑„É™„Éľ„āļťáĎŚĪě„ĀĆŚźę„Āĺ„āĆ„Āĺ„Āôś≤ĻŚúß„Éô„Éľ„É©„Éľ,TY43„ā∑„É™„Éľ„āļ„āĘ„É™„ā≤„Éľ„āŅ„Éľś≤ĻŚúß„Āõ„āďśĖ≠ś©ü,ty15„ā∑„É™„Éľ„āļ„ā¨„É≥„Éą„É™„Éľ„Āõ„āďśĖ≠ś©ü„Ā™„Ā©. ÁßĀ„Āü„Ā°„ĀĮŚłł„Āę„ÄĆŚģüÁĒ®ÁöĄ,ťĚ©śĖįÁöĄ,ŚÖąťßÜÁöĄ„Āč„Ā§ťÄ≤ŚŹĖÁöĄ".Ť®≠Ť®ą„ĀģŤĪäŚĮĆ„Ā™ÁĶĆť®ď„Ā®ś©üŚô®„ĀģŚá¶ÁźÜ„Āä„āą„Ā≥Ť£ĹťÄ†„ĀģŚĄ™„āĆ„ĀüŤÉĹŚäõ,„āíťĀĶŚģą„Āó„ÄĀ„Āē„Āĺ„ĀĖ„Āĺ„Ā™ťĚěś®ôśļĖ„Āģś≤ĻŚúßś©üśĘį„ā퍮≠Ť®ą„Āä„āą„Ā≥Ť£ĹťÄ†„Āß„Āć„Āĺ„Āôšł≠ŚõĹ„Āģť°ßŚģĘ.„Āę„āą„Ā£„Ā¶ťĀłśäě„Āē„āĆ„ĀüÁČĻŚą•„Ā™Ť¶ĀšĽ∂,„ĀęŚĺď„Ā£„Ā¶„ÄĀÁßĀ„Āü„Ā°„ĀĮšłĽŤ¶Ā„Ā™ŚĽÉś£ĄÁČ©„É™„āĶ„ā§„āĮ„ÉęšľöÁ§ĺ,Ś§ßŤ¶Źś®°„Ā™Ť£ĹťČĄśČÄ,Ť°õÁĒü„ā∑„āĻ„É܄Ɇ,„Ā™„Ā©.,„Āę„āĶ„Éľ„Éď„āĻ„ā휏źšĺõ„Āó„Āĺ„Āô„Äā ÁßĀ„Āü„Ā°„ĀĮ„ÄĀ„Éô„Éľ„É©„Éľ,„Āõ„āďśĖ≠ś©ü,„āĄś≤ĻŚúß„āĻ„āĮ„É©„ÉÉ„Éóś©ü,„Ā™„Ā©„Āģś≤ĻŚúßś©üśĘį„āíŤ£ĹťÄ†„Āô„āčśúÄ„āāśúČśúõ„Ā™ŚõĹŚÜÖŤ£ĹťÄ†šľĀś•≠„Āģ1„Ā§„Āę„Ā™„āä„ÄĀŚĽÉś£ĄÁČ©„É™„āĶ„ā§„āĮ„Éęś©üŚô®ś•≠ÁēĆ„Āꌧ߄Āć„Ā™ŚĹĪťüŅ„āíšłé„Āą„Ā¶„ĀĄ„Āĺ„Āô.„Äā śĶ∑Ś§ĖŚłāŚ†īŚźĎ„ĀĎ,śĶ∑Ś§ĖŚłāŚ†ī„ĀęÁ≤ĺťÄö„Āó„ĀüŚįāťĖÄ„ĀģŤ≤Ņśėď„ÉĀ„Éľ„Ɇ„ĀĆ„Āā„āä„Āĺ„Āô.ŚĹďÁ§ĺ„ĀģŤ£ĹŚďĀ„ĀĮśó•śú¨„ĀꍾłŚáļ„Āē„āĆ„Ā¶„ĀĄ„Āĺ„Āô,„É≠„ā∑„āĘ,„ā™„Éľ„āĻ„Éą„É©„É™„āĘ,ÁĪ≥ŚõĹ,ŤčĪŚõĹ,„ÉČ„ā§„ÉĄ,ŤčĪŚõĹ,„ā§„É©„É≥,ŚćóśĚĪ„āĘ„āł„āĘ„Āä„āą„Ā≥„ĀĚ„ĀģšĽĖ„ĀģŚõĹ„Ā®ŚúįŚüü.ŚĹďÁ§ĺ„ĀģťęėŚďĀŤ≥™„Āģ„ÉĎ„Éē„ā©„Éľ„Éě„É≥„āĻ„Ā®„āĶ„Éľ„Éď„āĻ„ĀĮ„ÄĀŚźĆśôā„ĀęśĶ∑Ś§Ė„Āģ„Éź„ā§„ɧ„Éľ.„ĀģŤ™ćŤ≠ė„Ā®Ť≤∑„ĀĄśąĽ„Āó„āíÁć≤Śĺó„Āó„Ā¶„ĀĄ„Āĺ„Āô,šłÄťÉ®„ĀģŚõĹ,ÁŹĺŚúį„ĀģŚõĹ„ÄÖ„Āę„āĶ„Éľ„Éď„āĻ„ā휏źšĺõ„Āô„āč„ÉĖ„É©„É≥„ÉČ„ā®„Éľ„āł„āß„É≥„Éą„ā퍮≠ÁĹģ„Āó„Āĺ„Āó„Āü.šĽ£ÁźÜŚļó„ÉĀ„Éľ„Ɇ„ĀꌏāŚä†„Āó„Ā¶ś•Ĺ„Āó„ĀĄŚćĒŚäõ„āíťĖčŚßč„Āô„āč„Āď„Ā®„āíŚŅÉ„Āč„āČś≠ďŤŅé„Āó„Āĺ„Āô. ŚįāťĖÄŚģ∂„ÉĀ„Éľ„Ɇ „āĽ„Éľ„Éę„āĻ„ÉĀ„Éľ„Ɇ,„ĀģŤ®≠Ť®ą„ÉĀ„Éľ„Ɇ„Ā®„āĘ„Éē„āŅ„Éľ„āĶ„Éľ„Éď„āĻ„ÉĀ„Éľ„Ɇ„ā팟ę„āÄŚįāťĖÄŚģ∂„ÉĀ„Éľ„Ɇ„ĀĆ„ÄĀŤ≥ľŚÖ•„Éó„É≠„āĽ„āĻŚÖ®šĹď„āíťÄö„Āó„Ā¶„ĀäŚģĘśßė„āí„āĶ„ÉĚ„Éľ„Éą„Āó„Āĺ„Āô.„Äā ÁĶĆť®ďŤĪäŚĮĆ„Ā™ŚäīŚÉćŤÄÖ ÁßĀ„Āü„Ā°„ĀģŚ∑•Ś†ī„Āę„ĀĮ„ÄĀ„Āď„Āģś•≠ÁēĆ„Āß10ŚĻīšĽ•šłäŚÉć„ĀĄ„Ā¶„Āć„Āü20šļļšĽ•šłä„ĀģÁĶĆť®ďŤĪäŚĮĆ„ĀßÁÜüÁ∑ī„Āó„ĀüŚäīŚÉćŤÄÖ„ĀĆ„ĀĄ„Āĺ„Āô.„Äā ťęėŚďĀŤ≥™„ĀģŤ£ĹŚďĀ śąĎ„ÄÖ„ĀĮśĆĀ„Ā£„Ā¶„ĀĄ„Āĺ„Āô „ĀäŚģĘśßė„ĀęśúÄťęė„ĀģŚďĀŤ≥™„ā휏źšĺõ„Āô„āč„Āü„āĀ„Āģ„Āô„ĀĻ„Ā¶„ĀģŤ£ĹŚďĀ„ĀģŚé≥ś†ľ„Ā™Ť£ĹŚďĀŚüļśļĖ,„Äā„É≠„Éľ„ÉČ„Āô„āčŚČć„Āę„ÄĀ„Āô„ĀĻ„Ā¶„ĀģŤ£ĹŚďĀ„Āģ„ÉÜ„āĻ„Éą„ā퍰ƄĀĄ„Āĺ„Āô.„Äā ť°ßŚģĘ'ŤČĮ„ĀĄ„Éē„ā£„Éľ„ÉČ„Éź„ÉÉ„āĮ „ĀäŚģĘśßė„ĀĮÁßĀ„Āü„Ā°„ĀģŤ£ĹŚďĀ„ĀęťĚ쌳ł„ĀęśļÄŤ∂≥„Āó„Ā¶„Āä„āä„ÄĀťē∑„ĀĄťĖďÁßĀ„Āü„Ā°„ĀęŚćĒŚäõ„Āó„Ā¶„ĀŹ„āĆ„āč„Āď„Ā®„āíśúõ„āď„Āß„ĀĄ„Āĺ„Āô.„Äā

Ť©≥Áīį„ā퍶č„āč

šĹŹśČÄ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

šĹŹśČÄ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

fran√ßais —Ä—É—Ā—Ā–ļ–ł–Ļ

—Ä—É—Ā—Ā–ļ–ł–Ļ espa√Īol

espa√Īol ōßŔĄōĻōĪō®Ŕäō©

ōßŔĄōĻōĪō®Ŕäō© TiŠļŅng ViŠĽát

TiŠļŅng ViŠĽát šł≠śĖá

šł≠śĖá

IPv6„Éć„ÉÉ„Éą„ÉĮ„Éľ„āĮ„āí„āĶ„ÉĚ„Éľ„Éą

IPv6„Éć„ÉÉ„Éą„ÉĮ„Éľ„āĮ„āí„āĶ„ÉĚ„Éľ„Éą